Before utilizing the roadheader, it's crucial to inspect the roadheader. Generally, we'll check the elements of the roadheader. As soon as we check that there are no issues with the elements of the roadheader, we can utilize it and the roadheader can play much better. It's efficacy.

Let us take a peek at what the main areas of the roadheader check.

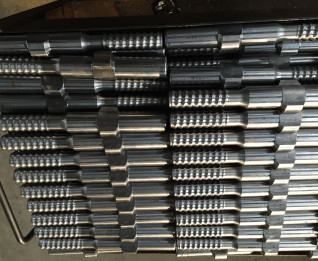

1. Assess the cutting head: if any selections are damaged, lost, or replaced with fresh ones. 2. Check the tooth for cracks and wear.

3. Assess the cutting armFill out the cutting arm. If the amount of lubricant is insufficient, it has to be replenished in time.

4. Examine the equipment unit: Assess abnormal vibration and sound. The amount of oil was observed by an oil level gauge.

5. Check for abnormal temperature rise. Whether the bolts are loose or not.

6. Check the walking segment: Is the strain of this track ordinary? Whether the track shoe is damaged or not. Whether each wheel rotates.

7. Examine the blade section: The spinning of the star wheel is ordinary.

These roadheader components are indispensable for inspection. If issues are found during the inspection, it is possible to go to the repairs. Generally, the glitch can be fixed by yourself. If the fault is severe, you can ask the maintenance staff to do the repair. Do not forget to lubricate those machines regularly.

As a Top Hammer Tools Manufacturer exporting Dth Hammer, we have the responsibility and obligation to provide you with maintenance advice. If you have any problems, please do not hesitate to contact us.

Copyright © Guiyang Top Equipment All Rights Reserved

Sitemap | Powered by